By John Reese

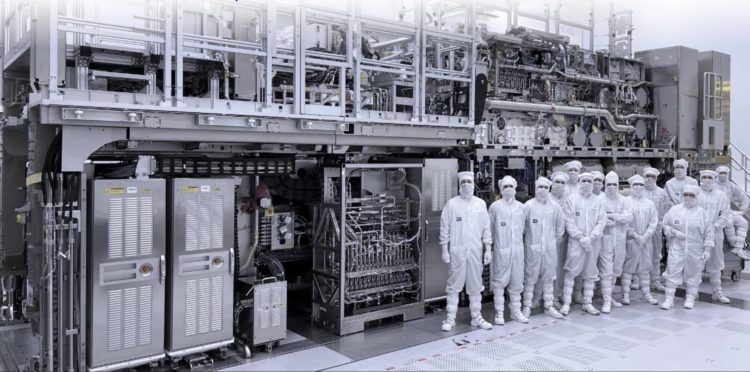

At the August 9 meeting Fred Wu introduced Dr. Timothy A. Brunner, PhD, who gave a talk on “Extreme Ultraviolet Lithography: Making the Next Generation of Computer Chips.” Brunner is an acknowledged expert in this field, with more than 40 years’ experience and numerous publications and awards.

He delivered the answer to how so much processing power can be contained in such a small device as a modern-day smartphone, tablet, or ultra-thin laptop. Essential to this ongoing progress is continued miniaturization of computer chip circuitry. Computer circuits are fabricated from silicon wafers by a complex process involving hundreds of steps, but the most critical steps are the printing of microscopic circuit patterns onto wafers. The printing process, which uses light rays to project the pattern onto a wafer, is called lithography. To keep making chips faster, more powerful, and less expensive, these patterns must get finer and finer, and the key to projecting finer patterns is to use shorter wavelength light. In the 1980s, lithography used blue light because its wavelength is shorter than green or red. In the 2000s, ultraviolet light was used. The most advanced chips today must be printed with “extreme” ultraviolet light (EUV).

While it is easy to build a source of blue light, or even ultraviolet light, generating EUV is very, very challenging. It takes the largest commercial laser made firing 50 thousand times a second at a molten drop of tin to produce bright bursts of light at the right wavelength. Painstakingly researching how to do this was a major breakthrough. EUV is not only difficult to produce, it is also strongly absorbed by air, as well as the glass used in a lens to focus the rays. In addition, multiple super fine patterns must be printed on top of one another during the course of wafer processing, and the patterns must be overlaid with phenomenal precision, or the chip will not work. To put this required precision into a human scale, compared to a wafer scaled to the size of Lake Tahoe, the deviation can be no more than the width of a human hair.

How can a machine produce EUV and guide it to form submicroscopic patterns precisely overlaid on previously printed layers on a silicon wafer, at a speed of thousands of chips per minute? The technology described in this presentation sounded like science fiction, but EUV lithography is the driving force in high volume chip manufacturing today.

The latest technology Dr. Brunner worked on was able to shrink the size of a computer memory cell by an astounding 91% over the prior generation. Less than 20 miles from Greenwich, ASML in Wilton is the only producer of the extreme ultraviolet lithography machines that are needed to manufacture the most advanced chips. The machine that the ASML company sells to do this is priced at $150 million and is so big and heavy that it takes a 747 plane to transport each of the four modules that comprise one machine. This equipment is not allowed to be sold to the Chinese.

To see the full presentation, go to https://greenwichrma.org, cursor to “Speakers” and click on “Speaker Videos.”

Note: The views expressed in these presentations are those of the speakers. They are not intended to represent the views of the RMA or its members.

RMA speaker presentations are presented as a community service at no cost to in-person or Zoom attendees, regardless of gender. The RMA urges all eligible individuals to consider becoming a member of our great organization, and thereby enjoy all the available fellowship, volunteer, and community service opportunities which the RMA offers to its members. For further information, go to https://greenwichrma.org/, or contact our membership chairman (mailto:members@greenwichrma.org).